Why Register?

- List Your Business

- Business Matchmaking

- WhatsApp Chat

- Personal Messaging

- Showcase Your Products

Product Pictures

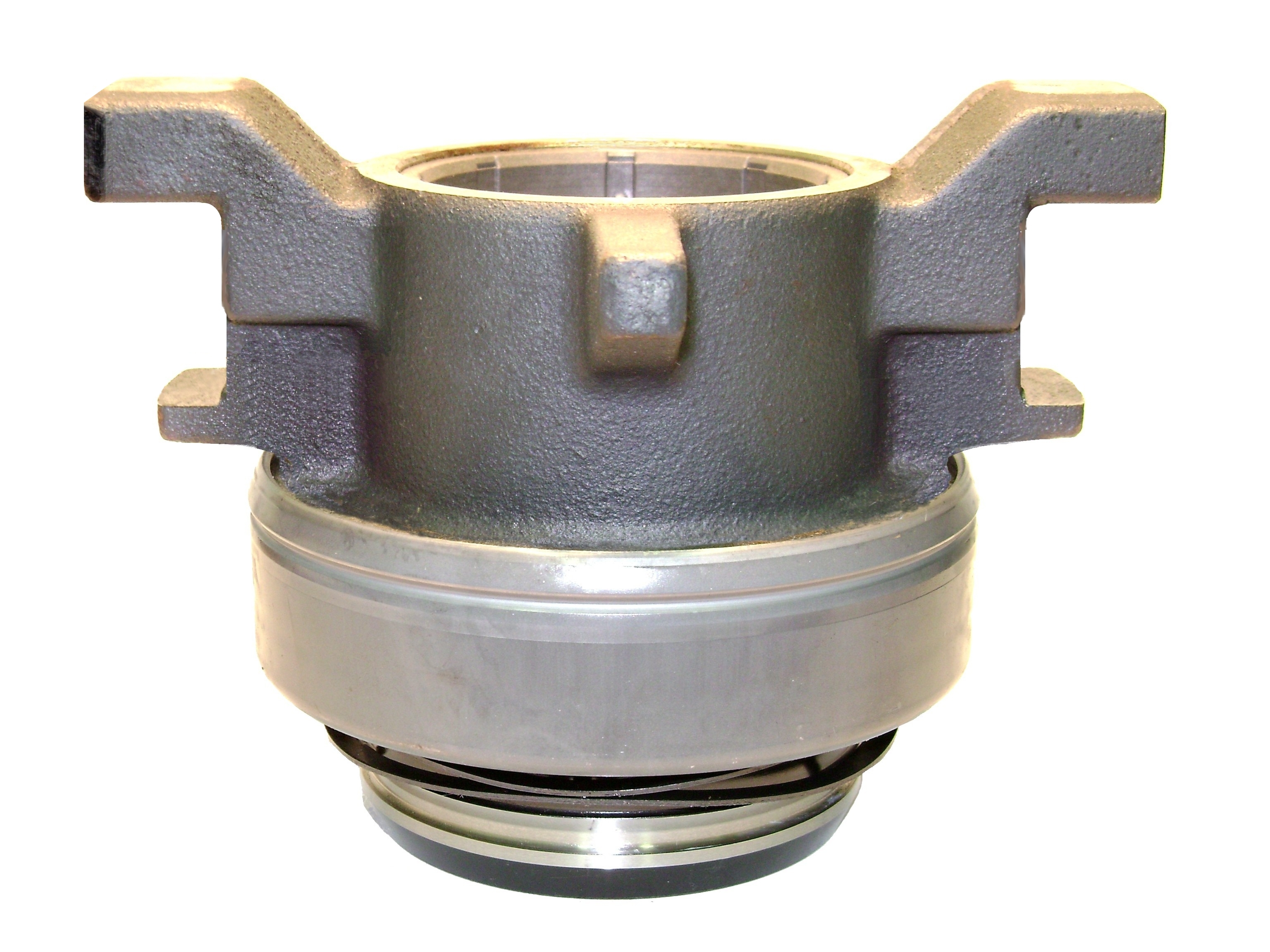

SNT lndustriale has been for many years a leading company in the manufacturing of clutch release bearings for cars and trucks, belt tensioners c:nd wheel bearings. Products quality is guaranteed by skilled staff technically prepared and integrated use of software systems for aided design, which also allow our brand to be one of the most popular and appreciated on International level. High-tech CNC machines guarantee the right execution from production to assembling and laboratory analysis assure high quality over time, processes testing and continuous development of our range. Particular attention is given to the quality management system with achievement of ISO 9001- 2008 certification that follows the products up to shipment.

SNT Industriale has been from many years a leading company in the production of clutch release bearings for heavy and light duty vehicles and passenger cars.

Highest quality of the products, guaranteed by skilled staff technically prepared and integrated use of a software system for aided design, also allows the brand to be one of the most popular and appreciated on international scale.

At SNT Industriale, innovation is the engine of growth, and in a market constantly modifying, the ability of renew and innovate is appointed to be ever and ever important; it’s easy to understand how development (R&D) of new components gains a decisive role to maintain competitiveness and satisfaction of customers.

QUALITY & TECNOLOGY

At SNT Industriale, innovation is the engine of growth, and in a market constantly modifying, the ability of renew and innovate is appointed to be ever and ever important; it’s easy to understand how development (R&D) of new components gains a decisive role to maintain competitiveness and satisfaction of customers.

Particular attention is given to the system quality management with achievement of ISO 9001-2008 certification. The experience and technical knowledge of SNT Industriale are available to customers who requires constant quality, top class assistance and optimal quality-price conditions.

From 2011 SNT Industriale expands its products’ range inserting on catalogues numerous items to cover more and more applications of all the European brands of industrial vehicles: DAF, Iveco, MAN, Mercedes Benz, Renault, Scania, Volvo.

On 2015 SNT Industriale implemented a new lathe inclusive of a automatic station and anthropomorphic robot and a new CMM machine to update and raise production as well quality of our products.

Starting from September 2016 will also implemented a new lathe and a new work center to face continuous increases of production, indicator of the high quality stated by our products, more and more required by the market.

Started in this way a new period of raising and development thanks to numerous investments by the installation of machineries and laboratories’ equipments in order to support the more and more sophisticated productive processes and a continuous improvement of the quality, further than the extension of the range of articles, focusing to releasers for heavy-duty vehicles.

On 2004, the new offices and production site have been inaugurated with further enrichment of machineries for production, improvement of the warehouse and development of new equipments to control the quality.

Our technical department handles all the phases of research and development process, starting from design in CAD 2D/3D to industrialization of the product through every level of manufacturing.

The in-line controls are arranged through specific control plans during the design and are executed at 100% through equipment as micrometer and digital calipers placed beside all the machineries in order to preventively identify the effective suitability of our releasers in every conditions.

Furthermore, to achieve final approval and preventive homologation of new developments, it has been realized a quality room with a new control desk that allows us to test the releasers simulating real operations of the clutches on the vehicles, either with functional tests of vibrations, mechanical noise and temperature of the bearings, or durability tests that simulate the entire life of the bearing and verify their reliability even in extreme conditions.